“It’s still in shambles”: How Boeing can come back from crisis

BBC

BBCThis has been a miserable year for Boeing. Not only has it struggled to cope with a safety and quality control crisis, it has lost billions of dollars following a strike by workers that paralysed production at two of its biggest factories.

Even its space programme has been in trouble. Two astronauts were left stranded on the International Space Station in June after their Boeing Starliner capsule developed a potential fault, which would have made returning to Earth in it too dangerous.

On top of all this, the company faces a crisis of confidence from within its own ranks, says Bjorn Fehrm, an aeronautical and economic analyst at industry consultants Leeham Company.

“People in Boeing don’t believe in words from top management any more,” he says.

Reuters

ReutersSam Mohawk is a 51-year-old quality assurance investigator at Boeing’s factory in Renton near Seattle, a huge plant where the 737 Max is built. It is the company’s best-selling aircraft, but one with a chequered safety record.

Earlier this year Mr Mohawk came forward as a whistleblower, claiming that chaos on the factory floor in the years since the Covid-19 pandemic had led to thousands of faulty or “non-conforming” parts going missing, and potentially being fitted aboard aircraft that have since been sent to customers.

“The whole system was just in shambles,” he says of that period. “It [had] kind of just broken down.”

His allegations came to light in June when they were referred to during a congressional hearing in Washington DC into safety failures at the aerospace giant.

During the session, Boeing’s top bosses were accused by Republican Senator Josh Hawley of “strip-mining” the company for profit and cutting corners on safety in order to boost earnings.

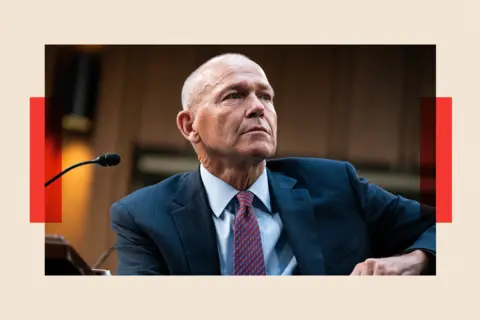

David Calhoun, who was Boeing’s chief executive at the time, said he “didn’t recognise” Mr Hawley’s depiction of the company. “That is not the way we operate,” Mr Calhoun said back then. “I am proud of every action we have taken.”

Getty Images

Getty ImagesSince then, Boeing has appointed a new chief executive, Kelly Ortberg, who has pledged to “restore trust” in the business, overhaul its corporate culture and prioritise the safety of passengers. The company is also in the process of implementing a comprehensive safety and quality plan, which was launched earlier in the year.

But according to Mr Mohawk, who still works at Boeing, the drive to build planes as quickly as possible in order to maximise revenues remains. The accountants, he insists, are “100%” running the operation.

“Nothing has changed,” says Mr Mohawk. “Our executives talk to the press and say, ‘quality and safety is our number one priority’. But it’s just the same.”

Boeing rejects Mr Mohawk’s claims. It insists they have been thoroughly investigated and that none of them were found to be valid.

In a statement, it said: “Boeing data systems do track parts, including non-conforming parts. The investigations into Mr Mohawk’s claims found no evidence that defective parts were installed on Boeing planes, and none of the issues raised affected safety.”

Alamy

AlamyAnother Boeing employee called Nathan (not his real name), who works in the company’s Everett factory in Washington state, where the 777 is built, describes low staff morale and corners being cut on the production line. Employees “don’t always follow the rules because they feel the pressure from their manager, and so they are not taking steps to ensure their own safety”, he claims.

But Mike Dunlop, an aerospace industry veteran and author of a book about turning around failing businesses, argues that Boeing has in fact already begun the process of transforming itself by going back to basics.

He believes many of Boeing’s problems result from the arrogance of the company’s management in the past, as it sought to cut costs in an effort to make more money. Recently, he says, there have been some improvements.

“I’ve seen the biggest changes in the company since the 1960s. What Kelly Ortberg is doing is focusing back on their core principles, which is to build airplanes as effectively and safely as possible, and be a reliable supplier to the airlines.”

Arguably, the market needs Boeing to be healthy. It remains a huge company, employing more than 150,000 people directly, and countless more in supply chains around the world. It is a significant contributor to the US economy.

But some insiders argue that it now has a credibility problem and needs to restore confidence.

Crashes and the 737 Max

Boeing’s challenging year began on 5 January with a routine evening flight from Portland International Airport in Oregon to Ontario, California. The plane, a brand-new Boeing 737 Max operated by Alaska Airlines, had taken off minutes earlier and was climbing when something went badly wrong.

“Er, yeah, we’d like to go down,” a female voice said over the radio as the crisis erupted at 16,000ft. “Alaska 1282 declaring an emergency… we’re descending to 10,000… we’re depressurised.”

Reuters

ReutersMoments earlier on the flight deck, First Officer Emily Wiprud had been exchanging routine messages with air traffic control, then there was a loud bang, a sudden rush of wind and her radio headset was torn off. Air pressure in the aircraft plummeted, as did the temperature.

Ms Wiprud and the captain hurriedly put on oxygen masks, then worked together with calm urgency to bring the damaged aircraft to the ground.

What had happened was deeply disturbing. A panel fitted over an unused emergency exit had not been bolted into place properly and had come away as the plane was climbing, according to the National Transportation Safety Board, which investigated the incident.

The passengers were still strapped in and no one was seriously hurt. But as investigators pointed out, it could have been much worse.

What made the incident stand out was the fact that the 737 Max was Boeing’s newest aircraft and its bestselling model in history.

Since its entry into service, more than 1,600 have been sent to airlines and a further 4,800 are on order. But even before this, its safety record was tarnished.

European Pressphoto Agency

European Pressphoto AgencyIn late 2018, an aircraft went down in the sea off the coast of Indonesia. Four months later another plane crashed minutes after take-off from Addis Ababa in Ethiopia. A total of 346 people were killed.

Both accidents were ultimately blamed on a poorly designed piece of flight control software. This had been fitted to address handling quirks on the new plane, and prevent pilots, who were used to earlier versions of the 737, from needing expensive retraining.

In practice, it became active at the wrong time, and forced both aircraft into catastrophic dives, according to investigators.

Did cost cutting ‘jeopardise safety’?

Some critics blame these accidents on a focus on the bottom line at the expense of safety. In a statement, The Foundation for Aviation Safety, which is chaired by ex-Boeing whistleblower Ed Pierson, said: “Attention to share price and profit margins alone has proven to be a flawed strategy.”

In the aftermath of those crashes, the 737 Max was grounded for 20 months as regulators examined every aspect of its design.

The company faced criticism over its corporate culture. A congressional report released in September 2020 found that Boeing’s rush to build new aircraft as quickly as possible while cutting costs had “jeopardised the safety of the flying public” – although its findings were described as “partisan” by one leading Republican.

EPA

EPAThe incident in Portland, however, was the result of the failure by Boeing engineers to bolt the door panel back on properly, after it had been removed to repair manufacturing flaws. Yet it placed the company in the spotlight again.

In particular, it drew attention to a series of continuing quality problems that had been occurring behind the scenes at the aircraft-maker and at its main supplier Spirit AeroSystems, which makes a number of large aircraft components including the main body.

These included manufacturing defects affecting parts of fuselages, tail and rudder assemblies, as well as sealants applied as protection against the effect of lightning strikes in central fuel tanks.

But the incident also placed a renewed focus on claims made by whistleblowers from within both companies, who had suggested that the pressure from Boeing to produce aircraft quickly, and ramp up production, had compromised safety on both the 737 and 787 programmes.

EPA

EPAThe sudden deaths of two other whistleblowers – John Barnett, who had worked in Boeing’s 787 factory in South Carolina, and Josh Dean, who had been employed by Spirit – generated further headlines in 2024. It resulted in pushing the wider story about Boeing once again into the news.

US politicians made their feelings clear. Richard Blumenthal, head of the Senate subcommittee on investigations said: “Boeing has put profits and speed of production ahead of quality and safety, and ultimately, that failing is at the core of its current difficulties.”

The strike that ‘cost Boeing $5.5 billion’

After the Portland incident, Boeing was ordered by the US Department of Transportation to produce a comprehensive action plan “to address its systemic quality control and production issues”.

The aerospace giant responded by publishing a detailed strategy aimed at improving its production systems, gaining more control over its supply chain, and encouraging employees to speak up on safety and quality control issues.

It also promised to strengthen its training programmes and overhaul critical processes on the production line.

Reuters

ReutersOn 1 July, Boeing reached an agreement to take control of Spirit as part of its efforts to resolve quality problems.

There were also changes at the top of the company when Mr Calhoun, who had become chief executive a year after the incidents in Indonesia and Ethiopia, stepped down and was replaced in August by Mr Ortberg, a veteran engineer who had spent decades in the industry.

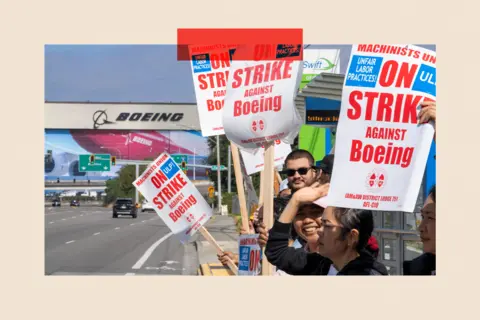

But weeks after his appointment, Boeing faced further crisis when more than 30,000 unionised workers – most of them in the company’s Washington State heartlands – went on strike over a new four-year contract, and how much Boeing would increase pay and other benefits for its workers.

The walkout, which began in September and lasted for seven weeks, held up production of the 737 Max, the 777 and the 767 freighter.

Getty Images

Getty ImagesIn the past, the company had become accustomed to negotiating from a position of strength, only this time it was in a weak position, and according to Bjorn Fehrm, employees were out for revenge.

“It was obvious to them that the old management had basically screwed them. That was the sentiment. They were absolutely disgusted with how they had been treated in the old contract,” he explains.

The result was a bitter dispute, at a time when the company was trying to instil a new working culture, and Mr Ortberg had promised to “reset” relations with its employees.

Boeing had to dig deep to come up with a deal that satisfied their demands, which included a 38% pay rise over four years. According to consultants Anderson Economic Group, the strike cost the company more than $5.5 billion.

Airbus versus Boeing: the fallout

All of this came at a time when the aerospace giant was already struggling financially. In the first nine months of 2024 it racked up losses of nearly $8bn (£6.3bn). As a result, it set out plans to cut 17,000 jobs, or a tenth of its workforce.

Boeing’s problems have taken a heavy toll on its business. Where once it went toe to toe with its European rival Airbus, it has now delivered fewer aircraft in each of the past five years.

In the first nine months of 2024 it distributed 291 planes to its customers, while Airbus provided 497, according to Forecast International.

For its customers, this has been frustrating. Ryanair, one of the biggest buyers of the 737 Max, has cut its growth forecasts for next year. In the US, Southwest Airlines has had to make job cuts.

Reuters

ReutersYet Airbus is not in a position to take full advantage of this. Its own order books are full to bursting, with a backlog of nearly 8,700 planes. Like its rival, it has experienced problems with suppliers, leading to delays.

Meanwhile, airlines want new planes. Estimates from both Boeing and Airbus suggest more than 40,000 new aircraft will be needed over the next two decades.

The current generation of aircraft are much more efficient and cheaper to run than their predecessors. So delays in renewing their fleets will cost airlines money – potentially leading to higher ticket prices for their passengers – as well as hampering efforts to improve their environmental performance.

According to Mr Fehrm, all this creates an opening for a third player to take a stake in the market. “Over the next five to 10 years there will be a gap between what the market is asking for and what Airbus and Boeing can deliver by thousands of aircraft.

“So it’s open for a third player. Brazilian manufacturer Embraer is a candidate. Or it’s going to be a chance for Comac, the Chinese supplier, to come into different markets and say, ‘Actually, we can do a decent job here.'”

A ‘borderline miraculous’ revival?

In early December Mike Whitaker, administrator of the Federal Aviation Administration (FAA), visited the factory in Renton near Seattle that Mr Mohawk has raised concerns about. At the time, Mr Whitaker said: “What’s truly needed is a fundamental cultural shift that’s oriented around safety, quality improvement and effective employee engagement and training.

“As expected, Boeing has made progress executing its comprehensive plan in these areas, and we will continue to closely monitor the results as they begin to ramp up production following the strike.”

But for many experts, the problems at Boeing go back decades – and are unlikely to be solved overnight.

“The hardest thing to change in large companies is the mindset of people,” says Mr Fehrm. “It takes time, and it needs to be manifested in actions, doing things differently.

“There are changes coming, but people won’t look at what the top management under Kelly Ortberg say. They will look for actions.”

Reuters

ReutersSome observers believe Mr Ortberg has an opportunity now to improve the company’s fortunes. Mr Dunlop thinks a change in mindset will be fundamental to Boeing’s future.

“The fastest way to turn around a company is to have a complete change in attitude on how you treat your employees, how you treat your customers, and most importantly in how you treat your suppliers.”

A complete reversal of its previous approach could produce a “borderline miraculous” revival, he believes.

But others are less confident. Captain Dennis Tajer, the lead spokesman for the Allied Pilots Association (the pilots’ union for American Airlines), believes real change at Boeing has to come, not from the boardroom, but from further down the company’s ranks.

“The solution is below senior management,” he argues.

“It’s at the middle management level, where you find the gatekeepers and the people who support doing things properly, not just keeping the schedule going.”

The stakes, he insists, could not be higher.

Top image credit: Alamy

BBC InDepth is the new home on the website and app for the best analysis and expertise from our top journalists. Under a distinctive new brand, we’ll bring you fresh perspectives that challenge assumptions, and deep reporting on the biggest issues to help you make sense of a complex world. And we’ll be showcasing thought-provoking content from across BBC Sounds and iPlayer too. We’re starting small but thinking big, and we want to know what you think – you can send us your feedback by clicking on the button below.

World News || Latest News || U.S. News

Source link